Knowledge Base

IMP offers a complete line of “plug and play” thermal transfer printer ribbons manufactured to meet or exceed the OEM specifications at significant cost savings. IMP’s mission is to provide the highest quality ribbon solutions, at competitive price levels, combined with the sales tools and support resources our reseller need to increase ribbon sales and profitability.

- IMP offers a full line of cost-savings ribbons for all automatic bagging systems and are guaranteed to be drop-in replacements for the OEM ribbon.

- International Media Products (IMP), a global leader in printing consumable supplies, is pleased to announce the official commencement of its operations in Mexico. IMP Mexico.

- IMP takes pride in prioritizing sustainability. Our goal is to lead efforts in reducing plastic waste, minimizing pollution, and promoting a greener printing industry.

- Introducing the most most competitively priced wax/resin ribbon - Z200+ - general purpose wax/resin ribbon.

- 2021 was a difficult year for all of us in the label and ribbon business. Despite resurgences in Covid-19, raw material shortages, supply chain constraints, and price increases, IMP reported record results for 2021, continuing our trajectory as the fastest growing ribbon supplier in North America.

- In this review of thermal transfer printing problems and solutions, we outlined the common problems, possible causes and solutions. Burn temperature guide and ANSI print quality samples are also included for your reference.

- When it comes to wax ribbons, there are a lot of options out there. IMP offers two grades thermal transfer wax ribbons, general purpose and premium. This article walks you through how to choose the appropriate grade of wax ribbon for your printing needs.

- Understand what is barcode and the different types of barcode. IMP offers a complete product lines of different ribbon formulation to meet your barcode printing needs.

- Like all of IMP's near edge ribbons, the skinny ribbons offer excellent heat, abrasion and chemical resistance as well as excellent image density and edge definition.

- As the world’s only vertically integrated producer of PET film and ribbon (PET film makes up over 50% of product cost) IMP provides the best price/performance value in the market. Learn how IMP's ribbons can help you reduce hidden cost and Total Cost of Ownership (TCO).

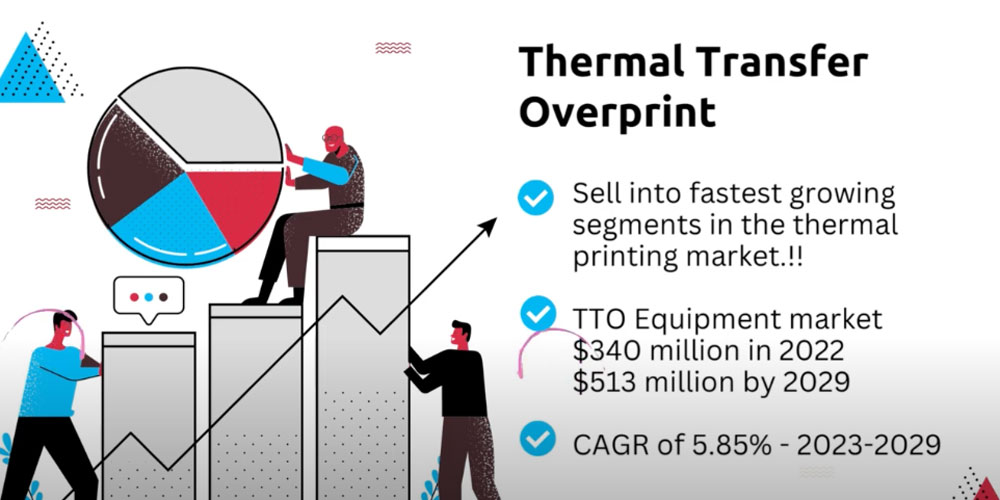

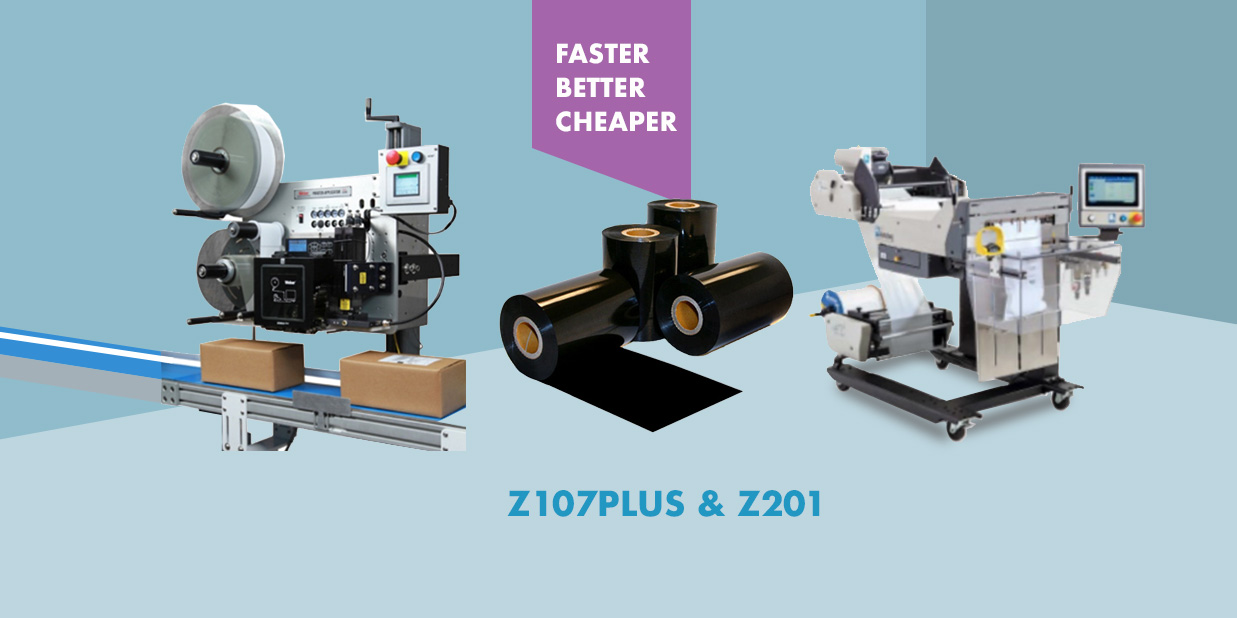

- The Printer Applicator and Automatic Bagging Systems markets are expected to be a high growth segment for thermal transfer printing over the next several years on a global basis. IMP provides faster, better and cheaper thermal transfer ribbons solutions for label applicator and automatic bagging systems.

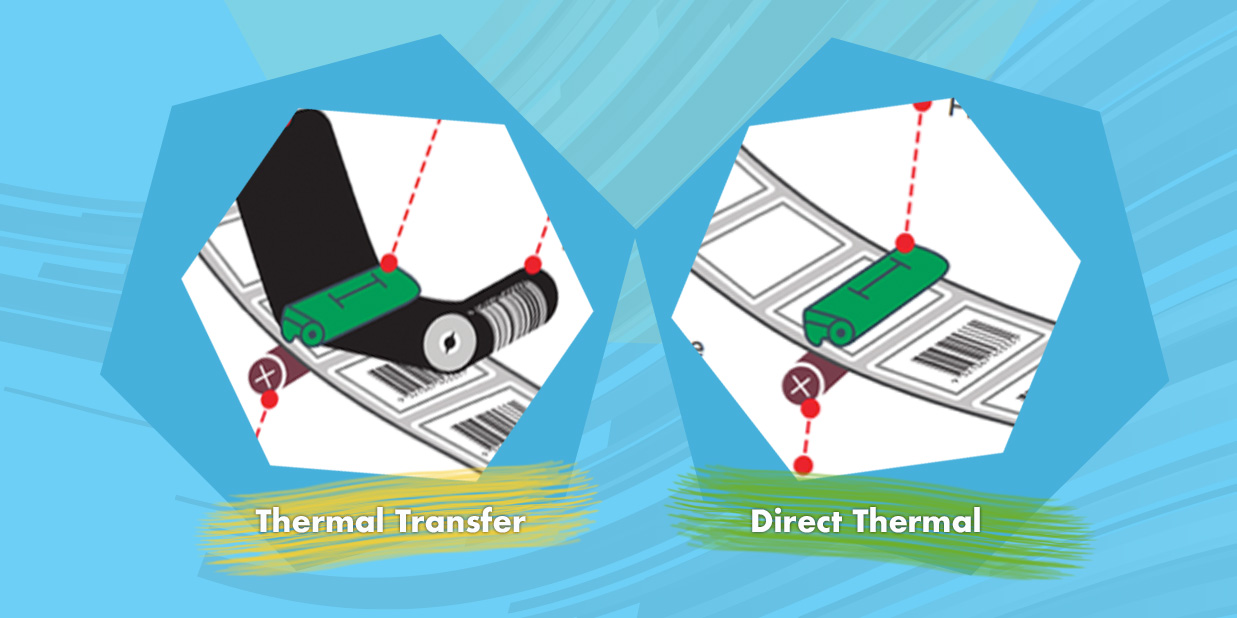

- Understand the defintion of Thermal Transfer Printing vs. Direct Thermal Printing, its printing method's advantages and disadvantages and how Thermal Transfer Printing can can bring you significant cost saving.

- IMP conducted a ribbon benchmarking comparison for Z107plus versus one of the industry leading resin enhanced wax formulations. The report shows that Z107plus provides a darker, more legible image, particularly at the higher speeds of 12, 14, and 16 ips.