Bar Code Basics!

What is a Barcode?

A barcode is an image that consists of a series of parallel black and white bars that can be read by a barcode scanner. Barcodes are applied to products to quickly identify them. Among their many uses, barcodes are typically used in retail stores as a part of the purchasing process, in warehouses to track and manage inventory and on invoices to help with accounting.

Why do we need barcodes?

The combination of black and white bars (also referred to as elements) represents varying text characters that follow a pre-established algorithm for that barcode (more on the types of barcodes later). A barcode scanner will read this pattern of black and white bars and translate them into a line of test that your retail point of sale system can understand.

Types of Barcodes

1-dimensional (1D) barcodes

1D barcodes are a series of black and white bars that can store information like a product’s type, size and color. You can find 1D barcodes on the top of universal product codes (UPCs) of a product’s packaging. This helps track packages through package delivery service providers like UPS and FedEx, the US Postal Service and Canada Post.

1-D (one dimensional) barcodes are read with any laser-based LED scanner. This barcode scanner works by illuminating the barcode with a red light, reflecting off of the black and white pattern. The pattern converts into code, which is then sent to a computer and deciphered.

2-dimensional (2D) barcodes

2D barcodes are more complex than 1D barcodes. They can include more information than just text, like price, inventory levels and even a product image. 2D codes require an imager scanner to be read properly. QR Code and Data Matrix examples are shown.

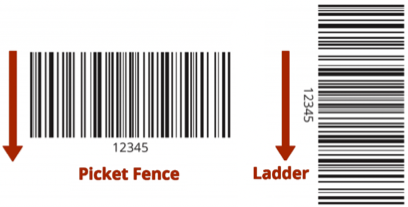

Rotated (Ladder) vs Non-Rotated (Picket Fence)

In general, printing a picket fence barcode involves heating the individual printhead elements for a longer length of time, depending on the height of the barcode. Barcode lines are in parallel with the print direction, so relatively easy for a ribbon to do.

Printing ladder barcodes require the printhead elements to heat and cool (on and off) in rapid succession because the barcode lines are horizontal to the print direction. This rapid firing of the printhead is more demanding on the ribbon performance and often requires a wax ribbon with a higher resin content, such as the Z107plus in order to provide good print resolution and edge definition.

IMP’s Complete Product Line

| Premium Wax | Wax/Resin | Resin | Near Edge / TTO |

|

IMP is your partner for innovative thermal transfer ribbon solutions which reduce the Total Cost of Ownership of Thermal Transfer Printing.

Reach out to us or contact your IMP representative today for pricing, free ribbon samples, or just to strategize on ways we can help you expand your ribbon and label sales.