Terminology for Thermal Transfer Products (Barcode Ribbon)

Thermal Transfer Printing

Thermal-transfer printing is a fast and clean digital printing method with no warm-up or cooling time required. During the print process, material is applied to paper or some other medium by melting a coating of ribbon so that it stays glued to the receiving material on which the print is applied. Thermal transfer printing is the standard for producing variables data such as barcodes and expiry dates etc., on-demand.

Thermal Transfer Ribbon (Barcode Ribbon)

Thermal transfer ribbon (barcode ribbon) is basically a roll of clear polyester (PET) film coated on one side with a colored pigment, or ink. The coating of the ribbon can be formulated using either wax, a mixture of wax and resin or pure resin. When the thermal transfer ribbon passes over the thermal print head, the heat produced by the print head causes the pigment or ink to transfer off the carrier film and bond to the label. As the manufacturer of thermal transfer ribbon, International Media Products (IMP) carries all three kinds of ribbons in our headquarter at Alpharetta, Georgia and Los Angeles, California.

Wax Ribbon

The ink component of thermal transfer ribbon (barcode ribbon) is formulated with wax. Wax ribbon is designed for printing onto paper labels, but please note that they must be kept in a dry environment, not subjected to chemicals or oil that would dissolve the wax image.

Wax-resin Ribbon

The ink component of thermal transfer ribbon (barcode ribbon) is formulated with a mixture of wax and resin. Resins provide the ribbon with excellent mechanical properties, but do not limit the printing speed or receptor compatibility. Wax-resin ribbons produce a finer image when paired with smooth paper or coated paper labels. Wax-resin is much more durable than wax, but should still avoid contact with water.

Resin Ribbon

The ink component of thermal transfer ribbon (barcode ribbon) is formulated with a mixture of pure resin. Pure resin ribbons are formulated to print onto plastic labels such as polyester and vinyl. Resin is designed to slightly dissolve into plastic surfaces, thus allowing it to become durable.

Hot Stamping Foil

Hot stamping foil is a printing process of using heat and pressure to apply metallic foil to materials such as light papers, carton board, laminated board, plastics and corrugated board.

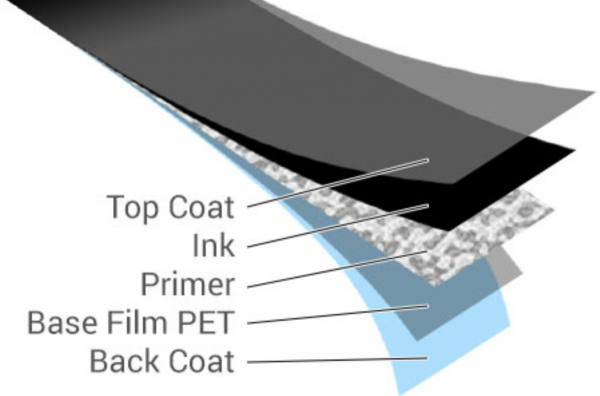

The structure of Thermal Transfer Ribbon (Barcode Ribbon)

The structure of Thermal Transfer Ribbon (barcode ribbon) is formed of multi-layers with ribbon core. For example, every ribbon type ink layer is designed to provide printing capability; the high strength construction minimize downtime caused by ribbon break; the advanced low friction back coating helps to reduce wear and static build up, allowing printhead to work longer; the core is optimized to ensure that ribbon replacement is as convenient as possible.

Thermal Transfer Ribbon Printer

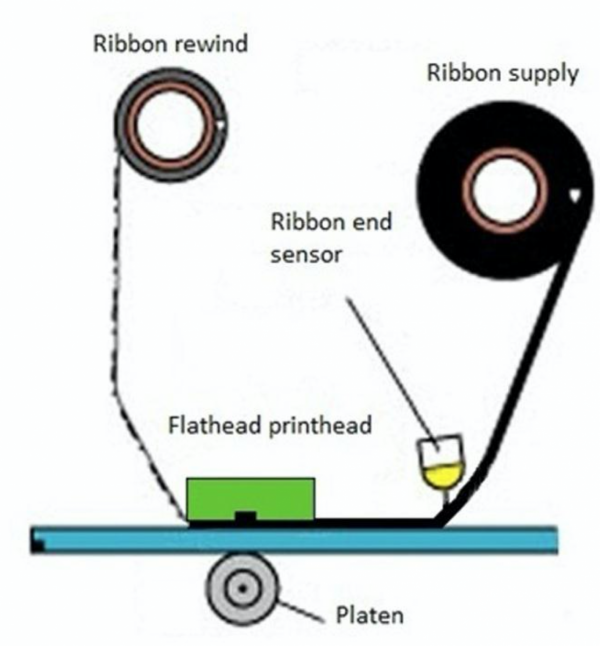

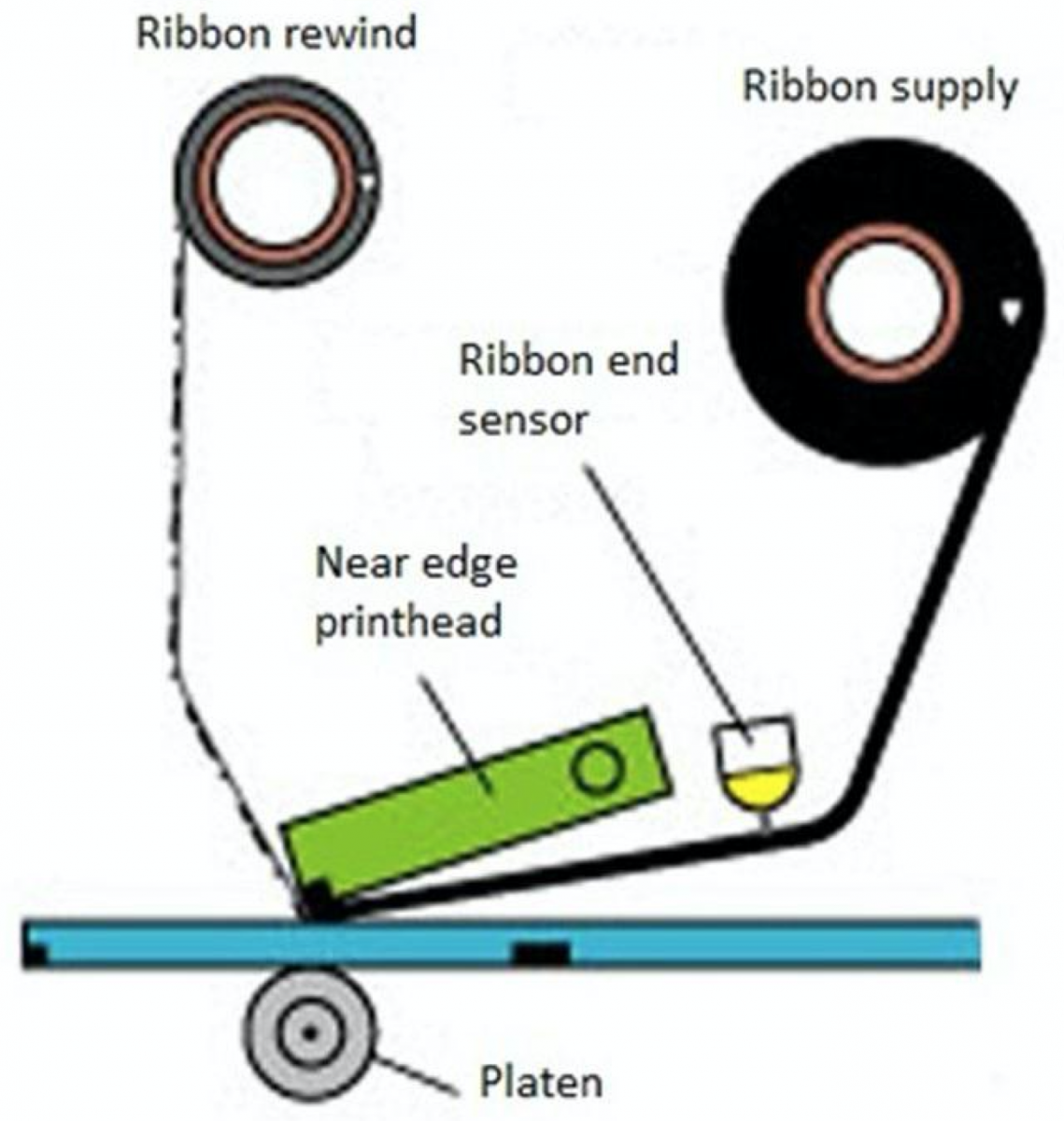

When the barcode ribbon is printed, the coated side contacts with the label, while the uncoated side transfer the heat to the ribbon and passes over the print head. The heat helps transferring the ink from ribbon to label. There are two types of print head technologies utilized in thermal transfer ribbon printing today: Flathead and Near Edge. They both offer increased efficiencies, while there are key differences to note between the two.

Flathead printer

Flathead printer is a heating-elements center-located horizontal printhead. As ribbon passes through the heating-elements, ink is dispatched to the substratum. This time the barcode ribbon and substrate travel horizontally to the front of the printer. Then the ribbon is separated from the substratum and directed to the take-up spindle. The flathead printhead is fixed. You can choose wax ink ribbons, wax/resin ribbons or resin black/color ribbons. The flathead printing speed is 14 its. The popular flathead printers are Zebra, Sato, Honeywell, TSC and Datamax.

Near-edge printer

Near-edge printer is a heating-elements edge-located 45 degree angled printhead. Near-edge printhead is also called floating head or corner edge. This technology provides fast printing speed (up to 40 ips) and automatically adjusts to the media thickness (up to 14 point). A lot of different media (such as magnetic tape, heat shrink, plants pens, etc) should be specified for the special applications. The unique ribbon chemistry limits ribbon type to wax/resin and resin black and color thermal transfer ribbon formulations. The common near-edge printers are Toshiba TEC and Novexx for tag and label printing, and Markem and Videojet for printing directly on to flexible packaging (TTO Thermal Transfer Overprint).

Other types printers

There are different types of thermal printers. Tabletop thermal printers are used as industrial printers for industrial and manufacturing printing applications. They are the largest and most heavy duty of all thermal transfer printers. The advantage of tabletop printers is to produce high volume printing at top speeds. They are either flathead or near edge print heads. Tabletop thermal printers also use many different types of paper, labels, tags, etc. Near-edge printing is normally used for high caliper stocks.

Desktop or mobile thermal printers

Desktop thermal printers usually use flathead technology. Since desktop printers are much smaller and lighter than tabletop printers, they are typically used for lower volume applications, such as retail, healthcare and point-of-sale. Desktop printers run at lower speeds and need less adjustments. Mobile thermal printers use direct thermal technology. Direct thermal printer does not require ribbons, the ink is in the label material.

Thermal Transfer Overprinter (TTO)

TTO is perfect for flexible packaging and typically use near edge technology. TTO is used for imprinting expiration dates, lot codes, barcodes, and text and images. The usages include snack foods, packaged produce, meats, medical devices, pharmaceuticals. etc. TTO can print at speed of 18 - 24 ips and some higher volume TTO can print up to 40 ips.