Near Edge Printing vs Flat Head Printing

Flathead and Near Edge Printing Overview

Flathead and Near Edge are two types of print head technologies utilized in thermal transfer printing today. While both flathead and near edge thermal transfer printing technologies offer increased efficiencies, there are key differences to note between the two.

How a Flathead Printing Works

In flathead printing, the print head is horizontal, and the heating elements are located in the center of the print head. As the ribbon passes over the heating elements, ink is transferred to the substrate. From there, the ribbon continues to travel horizontally towards the front of the printer where it is then directed upwards to the take-up spindle. Flathead printers can utilize either wax, wax/resin, or resin black and color thermal transfer ribbons.

Flathead Printing Benefits:

- Suitable for the most common applications such as standard shipping labels

- Low cost wax ribbons available.

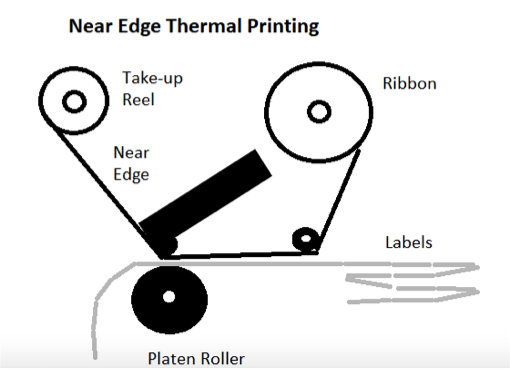

How a Near Edge Printer Works

To achieve higher print speeds, the near edge print head is angled approximately 45°, with the heating elements located at the edge of the print head. Since the media only comes in contact with the ribbon as it passes under the print head’s heating elements, the ink transfer must be instant. The distance between where an image is printed and where the ribbon and receiver separate from each other is significantly shorter when compared to flathead printers. Therefore, near edge ribbons must contain a release layer which allows the ink to quickly transfer to the substrate. This unique ribbon chemistry limits ribbon type to wax/resin and resin black and color thermal transfer ribbon formulations.

Near Edge Printing Benefits:

- Guarantees a perfect balance between high print speed and print quality

- Floating head which automatically adjusts to the thickness of the to be printed material

- Possible to print on the most extreme media (magnetic tape, heat shrink, plants pens…)

- Faster print speed – up to 40 ips

- Save up to 85% on ribbon usage (cf. Ribbon save)

IMP, the Thermal Transfer Ribbon Manufacturer, is your TTR Experts

As long-time industry veterans, we work with you to develop creative solutions to ensure success with your printer consumable program. IMP offers training and education, customized sales collateral, and the tools and support you need to grow your business.

We are the world's only vertically integrated producer of thermal ribbons. IMP extrudes PET base film and coats it in house. Since the base film represents over 50% of the cost of a ribbon, this is a true competitive advantage, use it! Vertical integration gives us outstanding quality control, consistency, ensures supply availability, and provides a lower total cost of ownership for the end user.

IMP’s Thermal Transfer Ribbon Offering

We offer a complete line of flathead thermal ribbons, which were designed to be "plug and play" replacements to the industry leading legacy products, at significant savings.

- Z908 General Purpose Thermal Transfer Wax Ribbon

- Z107plus Premium resin-enhanced Thermal Transfer Wax Ribbon

- Z201 Premium Wax/resin Thermal Transfer Ribbon

- Z300 Premium Resin Thermal Transfer Ribbon

We also have TTO/Near Edge ribbons, which are also "plug and play" replacements.

- Z212 Near Edge Wax/resin Thermal Transfer Ribbon

- Z213 Near Edge Premium Wax/resin Thermal Transfer Ribbon

- Z214 Near Edge High Yield Wax/resin Thermal Transfer Ribbon

- Z311 Resin Thermal Transfer Ribbon

Reach out to us or contact your IMP representative today for pricing, free ribbon samples, or just to strategize on ways we can help you expand your ribbon and label sales.