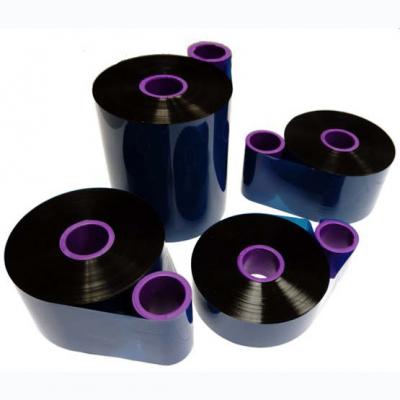

How to Select the Right Type of Thermal Transfer Ribbon (Barcode Ribbon) for Your Business

At IMP, our services go beyond just selling products and providing technology solutions. We share the best practices we have accumulated over the years to help our customers grow their business.

So how do you select the right type of thermal transfer ribbon for your thermal printing application?

- Each type of thermal transfer ribbon formulation has different performance characteristics which affect print quality, image durability and cost.

- The key to choosing the correct type of thermal transfer ribbon (barcode ribbon) involves a clear understanding of end use application.

Please find in below a map of our key product offering categories along with corresponding applications/usages and industries. We hope this information will help you navigate through our product portfolio and choose the right type of thermal transfer ribbon for your needs. If you have any further questions, please don’t hesitate to contact us. You can also request free samples for review.

Thermal Transfer Ribbon by Ribbon Formulation

General Purpose Wax Thermal Transfer Ribbons

Wax ribbons are the most economic ribbon solution and are primarily used to print onto paper labels.

Recommended Media: Coated and Uncoated Paper Label Stocks

APPLICATIONS:

- General purpose labeling

- Retail labels and tags

- Shipping, addressing, warehousing and receiving labeling

- Product identification

Premium Resin-enhanced Wax Thermal Transfer Ribbons

We offer several resin-enhanced wax-based ink formulas which provide high-quality printing at an economical price. Developed, designed and produced to printer manufacturers’ strict specifications, these ribbons offer excellent print quality for normal and rotated bar codes and small characters. These ribbons can also print at speeds as high as 16 IPS. Premium wax ribbons offer the best all-around performance when considering print quality, image durability, high speed printing capability and wider receiver material latitude.

Applications include:

- Shipping labels

- Product Identification

- Logistics labels

- Retail labels & tags

- Cold Storage film labels

- Lumber Tags

- Flexible Packaging

- Use with High Speed Applicators

- Rotated barcodes

Wax-Resin Thermal Transfer Ribbons

Wax/Resin ribbons are a mix of both wax and resin, which gives the printed labels more durability than the wax ribbons. The combination of the two allows printing onto a variety of materials, such as synthetics, coated or glossy paper stocks, and waterproof materials.

Applications include:

- Shipping, addressing, warehousing and receiving labeling

- Shelf and bin labeling

- Compliance labeling

- Health care applications

- Textile and apparel applications

- Nursery and lumber applications

- Printing directly on flexible packaging films

Resin Thermal Transfer Ribbons

Resin ribbons contain the highest content of resin and provide the best overall image durability, resistance to heat, high abrasion, and harsh chemical exposure. Designed for printing on durable label materials, such as synthetics, PET, BOPP, and other film substrates. Our resin formulas are UL approved.

Applications include:

- Outdoor applications

- Textile and apparel applications

- Nursery and lumber applications

- Chemical drum labeling

- Medical and pharmaceutical labeling

- Industrial applications

- Automotive applications

- Printing directly on flexible packaging films

Near edge TTO

We offer several premium wax/resin and resin formulation designed for Near-edge printers and TTO applications.

Applications include:

- General purpose labeling

- Retail tag and label applications

- Shipping, addressing, warehousing and receiving labeling

- Outdoor applications

- Shelf and bin labeling

- Compliance labeling

- Textile and apparel applications

- Nursery and lumber applications

- Chemical drum labeling

- Medical and pharmaceutical labeling

- Industrial applications

- Automotive applications

- Printing directly on flexible packaging films

Thermal Transfer Barcode Ribbon by Printing Substrate Material

This chart below provides a high-level overview on the print material compatibility for each of our barcode ribbon formulations, wax, wax-resin and resin.

| WAX | WAX-RESIN | RESIN | |

| TAG STOCKS | |||

| Uncoated Tag | ✔ | ✔ | |

| Coated Tag | ✔ | ✔ | |

| PAPER LABEL STOCKS | |||

| Coated Face Sheets | ✔ | ✔ | |

| Unocated Face Sheets | ✔ | ✔ | |

| Gloss Sheets | ✔ | ✔ | |

| ECONOMY SYNTHETICS | |||

| Polypropylene | ✔ | ||

| Vinyl (Topcoat) | |||

| Polyethylene | |||

| Polystyrene | ✔ | ✔ | |

| Polyolefin | ✔ | ✔ | ✔ |

| HIGH-END SYNTHETICS | |||

| Polyesters (Gloss Topcoat) | ✔ | ||

| Polyesters (Matte Topcoat) | ✔ | ✔ | |

| SPECIAL MATERIAL | |||

| Tyvek | ✔ | ✔ | ✔ |

| Tyvek Brillion | ✔ | ✔ | ✔ |

| Valeron | ✔ | ✔ | ✔ |

| Polyimide | ✔ | ||

| PVC Shrink Wrap | ✔ | ✔ | |

| Fabric Care Labels |