How Thermal Transfer Printing Works

Thermal Printer Basics

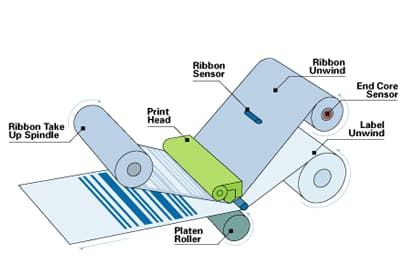

Thermal transfer printing is a digital technology that melts wax or resin-based inks from a ribbon onto paper, tape (made of nylon, polyester or vinyl), and even materials like heat shrink tubing to create an image. This is accomplished by the thermal printhead, which features heating elements with resolution from 203 to 600dpi (dots per inch).

The thernal printhead is controlled by a microprocessor, which determines which heating elements need to be activated in order to form a specific image. From there, signals are sent to the printhead, causing them to rapidly heat and cool against the ink ribbon, melting and transferring ink off of its backing film and onto the blank label surface.

Thermal Transfer Printing

- Substrate is fed through printer to print head

- TTR and substrate pass simultaneously under thermal printhead

- Ink from ribbon melts onto the substrate as it passes over the printhead, transferring the image to the substrate

- Printed substrate and ribbon are separated

- Finished product (e.g. printed label) emerges from printer

Advantages of Thermal Transfer Printing

- Durability: Thermal transfer printers can print signs and labels that stand up to extreme environments and meet OSHA and NFPA requirements, including arc flash labels, marine signage, safety signs, and more. Thermal transfer labels and tags are known for their smear-proof images and resistance to fading and are particularly well suited for creating barcodes.

- Less maintenance: With fewer moving parts, thermal printers tend to last longer, are easier to maintain, and run more reliably than other on-demand printers.

- Versatile: Thermal transfer printers can print documents, magnetized shelving labels, wire wraps, low-light visual communication labels, signs, text- and graphics-based floor marking, and labels meant for extreme conditions such as cold storage or auto-clave applications.

IMP - the Thermal Transfer Ribbon Manufacturer - is Your TTR Experts

As long-time industry veterans for thermal transfer ribbon manufacturing, we work with you to develop creative solutions to ensure success with your printer consumable program. IMP offers training and education, customized sales collateral, and the tools and support you need to grow your business.

We are the world's only vertically integrated producer of thermal ribbons. IMP extrudes PET base film and coats it in house. Since the base film represents over 50% of the cost of a ribbon, this is a true competitive advantage, use it! Vertical integration gives us outstanding quality control, consistency, ensures supply availability, and provides the most aggressive cost structure in the market.

IMP’s Thermal Transfer Ribbon Offering

We offer a complete line of thermal ribbons, which were designed to be "plug and play" replacements to the industry leading legacy products, at significant savings.

| Wax | Wax/Resin | Resin |

Buy direct from thermal transfer manufacturer and enjoy the saving! Reach out to us or contact your IMP representative today for pricing, ribbon samples, or just to strategize on ways we can help you expand your ribbon and label sales.